Marber: where your ideal packaging takes form.

We are a box factory with headquarters in Brescia, in the main Italian manufacturing quadrilateral - Turin, Milan, Verona, Bologna - specialised in manufacturing covered hard boxes.

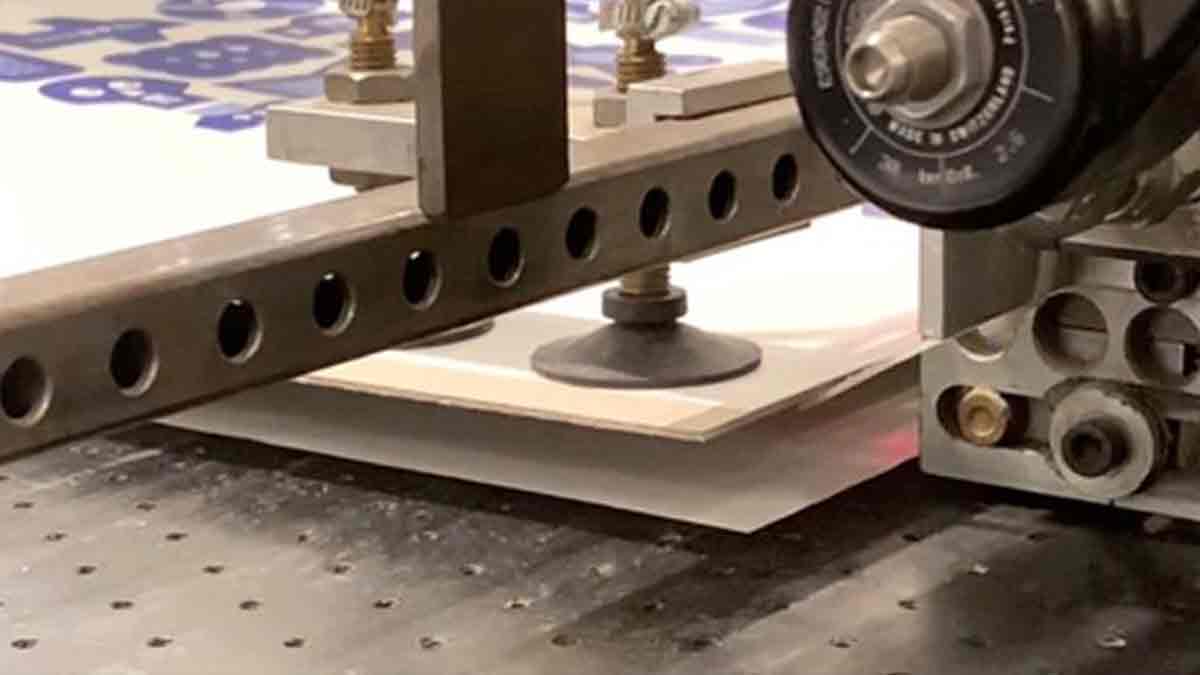

In the 5000 square meters of our factory in Verolanuova (BS), we manufacture paper and cardboard packagings, containers and recipients as well as cases and paper technology productsin any form and size.

This type of boxes is ideal for any type of product including toys, books, DVDs, cosmetics, wine bottles, footwear, shirts, leather goods, sweets, eyewear, diaries, labels etc. Would you like to design a different cardboard packaging for your product? We are ready and equipped to create a customised one for you.

Our offer also includes paper technology cases and articles with multicolour printing both offset and flexographic.

We boast of digital state of the art production lines, an advanced process control and corporate governance system as well as a creative department constantly committed to research and development of original products. These driving forces behind our success for over 50 yearshave put us in a position to constantly meet ever-new market demands on covered boxes.